Home > News

> News Information

Home > News

> News Information

1、 In the cover mold, the function of the deep drawing sill (deep drawing rib) is as follows:

1. Increasing the feed resistance can provide sufficient tensile stress on the surface of the deep drawn part, improve its stiffness, and reduce defects such as concave surfaces, deformation, relaxation, and ripples caused by springback;

2. Adjust the flow of materials to achieve uniform flow resistance in various parts during the deep drawing process, or to ensure that the amount of material flowing into the mold meets the needs of various parts of the workpiece, in order to prevent the phenomenon of "more wrinkles and less cracks";

3. Expand the adjustment range of edge pressure. On a double action press, adjusting the height of the four corners of the outer slider can only roughly adjust the edge pressure, and cannot fully control the feeding amount in various places to meet the needs of the workpiece. Therefore, it is necessary to use the edge ring surface and deep drawing ribs to assist in controlling the pressure in various places.

4. When there are deep drawing ribs, the requirement for the surface roughness of the edge ring can be reduced, which reduces the manufacturing difficulty of the deep drawing die for large covering parts; Meanwhile, due to the presence of deep drawing ribs, the gap between the upper and lower edge surfaces is increased, thereby reducing the wear of the edge surfaces and extending the service life of the mold.

5. Correct material unevenness defects and eliminate the possibility of slipping. Because when the material flows into the concave mold after being undulated by the deep drawing ribs, it acts as a leveling effect by rolling.

2、 The role of process cuts in large coverings

When it is necessary to punch out some deep local protrusions or bulges in the middle of the cover, during deep drawing, the workpiece often breaks locally because the material cannot be replenished from the outside of the blank. At this point, it is possible to consider punching process cuts or holes at appropriate positions in the locally protruding deformation zone, so that the easily broken area can be replenished with material from within the deformation zone.

3、 How to make cutting process incisions

There are two processing methods for stamping process incisions:

1. Punching out during material dropping, this method is used in situations where the local forming depth is shallow.

2. Cutting off during the deep drawing process is a common method that can fully utilize the plasticity of the material, that is, at the beginning of stretching, the radial extension of the material is utilized, and then the process incision is cut off. By using tangential extension of the material, a greater forming depth can be obtained. When cutting process holes during deep drawing, the tearing process is often used, which cannot completely separate the materials. The cut waste can be cut off together during the later trimming process, otherwise it is difficult to remove the waste from the mold.

4、 Layout principles of process incisions

The size and shape of the incision depend on the area it is located in and the requirements of its external auxiliary materials. Generally speaking, the following principles should be followed:

1. The incision should be adapted to the shape and contour of the local protrusion to allow the material to flow reasonably.

2. There should be sufficient overlap between the incisions to tension the material in the convex mold, ensuring clear molding and avoiding defects such as wrinkling, thereby ensuring good quality of the flanged hole edge after trimming.

3. The cutting part (i.e. opening) of the incision should be close to the edge of the protruding part or the area that is prone to rupture.

4. The number of incisions should ensure that the material deformation of all protruding parts tends to be uniform, otherwise wrinkles may not be prevented.

5、 Which stamping production must use precision progressive dies

In large-scale stamping production, thinner materials and high-precision small and medium-sized stamping parts must use multi station precision progressive dies. For larger stamping parts, it is suitable for stamping processing of multi station transfer molds.

6、 What are the requirements for vulnerable parts in precision molds

Precision molds have complex structures, high manufacturing technology requirements, and relatively high costs. In order to ensure the longevity of the entire mold, it is particularly required that the mold parts can be quickly replaced after damage or wear, which is convenient and reliable. Therefore, it is required that the important parts of the mold have interchangeability, and such mold parts have interchangeable stamping dies, which are called interchangeable stamping dies.

7、 The significance of layout design for precision progressive dies

Reasonable layout design can coordinate the processing of various workstations in the mold, greatly improving material utilization, manufacturing accuracy, productivity, and mold life, while also reducing the difficulty of mold manufacturing. Therefore, layout design is the most critical comprehensive technical issue in precision progressive die design, which requires comprehensive analysis and judgment of stamping direction, deformation frequency, corresponding deformation degree, possibility of mold structure, and processing technology of parts to make layout more reasonable.

8、 What is the carrier

When the progressive die is working, the object that transports the billet to various workstations for various punching and forming processes is called the carrier. The part where the carrier is connected to the billet is called the edge, and the part where the billet is connected to the billet is called the joint. In work, dynamic machining always requires the carrier to maintain stable feed and accurate positioning, therefore, the carrier is required to have a certain strength.

9、 What are the requirements for the mold seat in precision progressive dies

Precision progressive dies require high strength, good rigidity, and high precision of the mold. Therefore, structural steel is usually used as the mold seat, and its thickness requirement is thicker than the standard mold seat. The upper mold seat is thickened by 5-10 millimeters, and the lower mold seat is thickened by 10-15 millimeters.

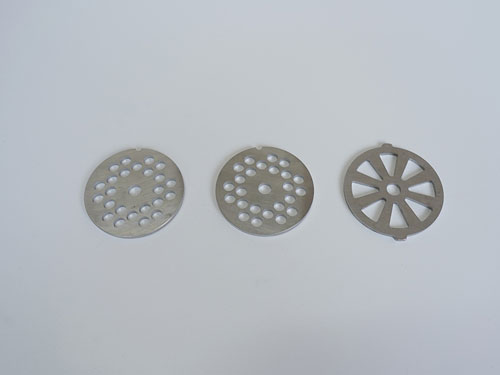

10、 What are the types of concave mold structures

There are three common types of concave mold structures: integral, block, and embedded. In ordinary stamping molds, standard concave templates are usually used as integral concave molds; In precision progressive dies, commonly used are block type dies and embedded block type dies.

.jpg)