Home > News

> News Information

Home > News

> News Information

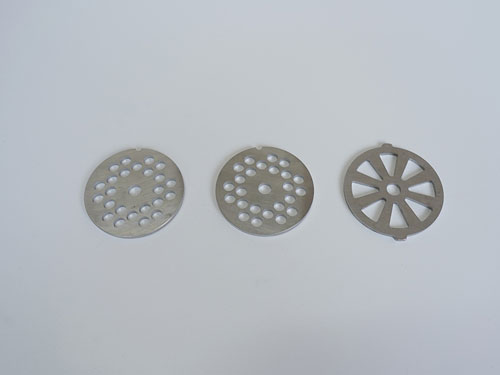

In the food processing industry, the cutting and slicing disc is a key equipment component, and its performance and accuracy directly affect the quality and production efficiency of the final product. In order to meet the processing needs of different food ingredients, from fine vegetable shreds to uniform meat slices, the customized processing process of the slicing knife disc is particularly important. Below, we will delve into this complex and intricate manufacturing process, from design planning to finished product inspection, where every detail carries the relentless pursuit of quality.

1、 Requirement analysis and customer communication

Everything begins with a profound understanding of customer needs. Before customizing the cutting and slicing disc, the technical team will have detailed communication with the customer to clarify key indicators such as processing objects (such as vegetables, fruits, meat, etc.), target output, slicing or slicing specifications (such as thickness and width), material requirements (such as stainless steel grade), durability, and ease of cleaning and maintenance. Through detailed requirement analysis, ensure that the design scheme can accurately meet customer needs and lay a solid foundation for subsequent processing.

2、 Design planning and material selection

Based on the results of the requirements analysis, the design team will use CAD (Computer Aided Design) software to perform 3D modeling of the cutterhead. In the design, it is necessary to comprehensively consider the arrangement of blades, angle setting, sharpness maintenance mechanism, as well as the stability and balance of the overall structure. At the same time, high-quality stainless steel materials are carefully selected based on the characteristics of the ingredients and usage scenarios to ensure that the blade remains sharp, corrosion-resistant, and easy to clean even after long-term use.

3、 Precision machining and heat treatment

Entering the production stage, precision machining is the first step. This process includes various techniques such as CNC milling, grinding, and wire cutting to ensure that the shape, size, and angle of the blade meet the design requirements. Especially in the processing of the blade, high-precision grinding technology is used to ensure that the blade is sharp and uniform, in order to achieve the best cutting effect. Subsequently, heat treatment is carried out to enhance the hardness and wear resistance of the blade, while maintaining sufficient toughness to prevent fracture during use.

4、 Assembly debugging and performance verification

After completing the processing of a single blade, enter the assembly process. During the assembly process, it is necessary to strictly control the fitting accuracy between each component to ensure smooth operation of the cutterhead without abnormal phenomena such as vibration and noise. After assembly, strict performance tests are conducted, including cutting efficiency, cutting quality, energy consumption, etc., to ensure that the performance of the cutterhead meets the expected standards. At the same time, durability testing is conducted by simulating actual usage scenarios to verify the stability and reliability of the cutterhead under long-term high load operation.

5、 Personalized customization and optimization

In response to customers' special needs, such as cutting or slicing specific shapes, or optimizing designs for specific ingredients, the technical team will provide personalized customization and development. By adjusting the blade shape, optimizing the cutting path, or introducing intelligent sensing technology, more precise and efficient machining results can be achieved. In addition, we also pay attention to the continuous optimization and upgrading of our products, regularly collect customer feedback, combine market trends and technological progress, iterate the design of the cutterhead, and continuously improve the performance and user experience of our products.

6、 Strict quality control and finished product inspection

Throughout the entire production process, we implement a strict quality control system, where every step from raw material storage to finished product release undergoes rigorous inspection. The finished product inspection process is of paramount importance, utilizing advanced testing equipment and scientific methods to comprehensively evaluate the dimensional accuracy, surface quality, sharpness, durability, and other aspects of the cutterhead, ensuring that every product meets the highest quality standards. Only knives that have passed strict inspection can be labeled as qualified and ready to be sent to customers.

7、 After sales service and technical support

We are well aware that high-quality after-sales service is the key to customer satisfaction. Therefore, we have established a comprehensive after-sales service system, providing all-round services including installation and commissioning, operation training, troubleshooting, and regular maintenance. At the same time, our technical team is always on standby to provide professional technical support and solutions to customers, ensuring that they can receive timely response and effective solutions to any problems encountered during use.

In summary, the customized processing of wire cutting and slicing cutters is a comprehensive project that integrates design, manufacturing, testing, optimization, and service. We always uphold the unremitting pursuit of quality and are committed to providing customers with the highest quality and most efficient food processing solutions. In the future development, we will continue to innovate technology, optimize processes, and enhance services, contributing our strength to the prosperous development of the food processing industry.

.jpg)